Quality control and testing are essential parts of the PCB assembly online technology process. Ensuring that every board produced meets strict standards and is free from defects can be a difficult task, but with best practices in place, organizations can guarantee their products will meet the highest expectations.

From designing tests to evaluating data, there are key steps all manufacturers must take for successful quality control and testing in PCB assembly online technology. This article will provide an overview of these best practices so organizations can ensure their boards meet specifications every time.

Establish Quality Control Standards

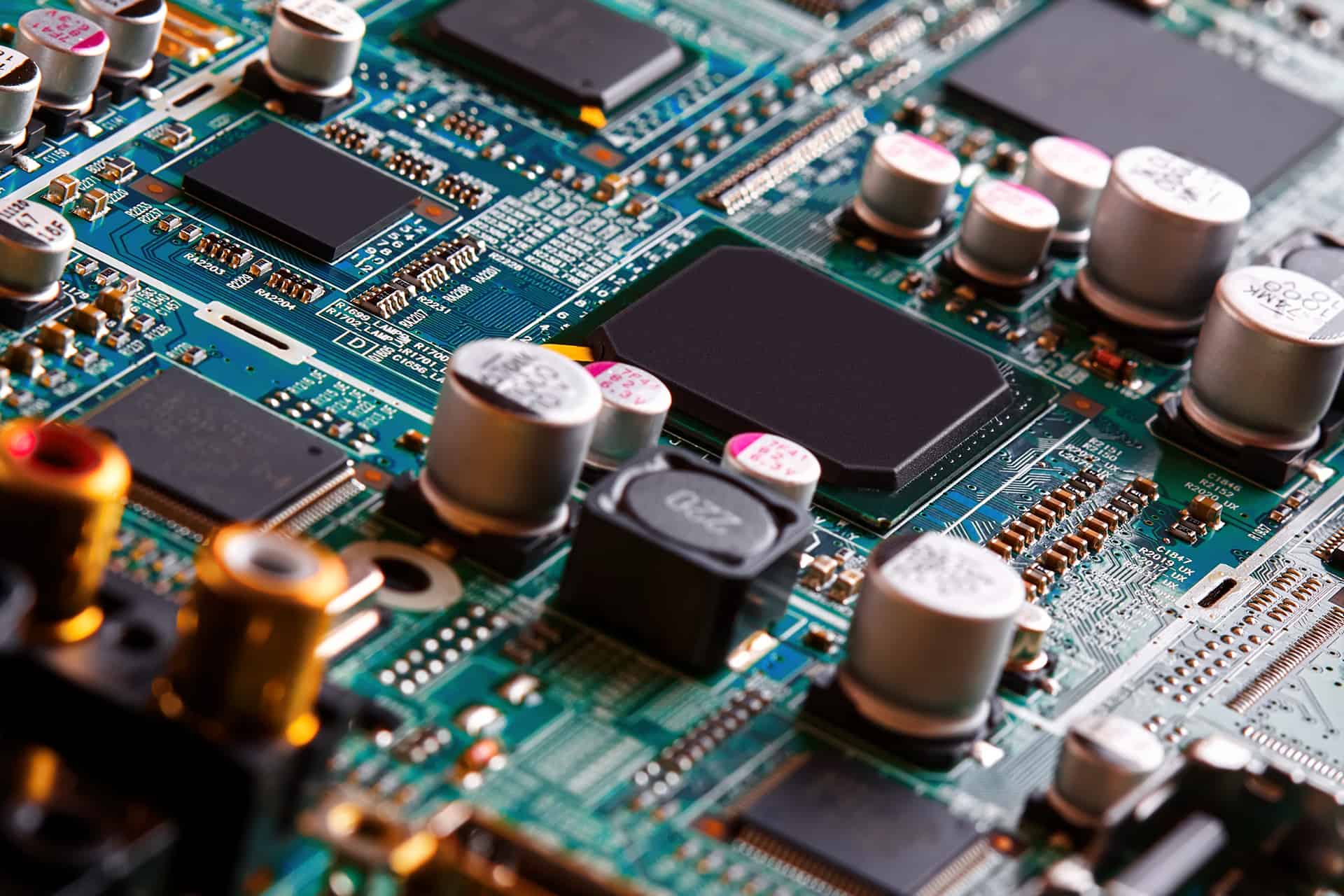

Establishing quality control standards for PCB assembly online technology is key to ensuring that the equipment and components used are reliable, durable, and safe. To do this effectively requires an understanding of the requirements of each stage of production as well as the best practices for inspecting, testing, and evaluating results. This can include examining electrical characteristics such as current-voltage ratings or analyzing visual elements like solder joint integrity or component placement accuracy.

Establishing quality control standards for PCB assembly online technology is key to ensuring that the equipment and components used are reliable, durable, and safe. To do this effectively requires an understanding of the requirements of each stage of production as well as the best practices for inspecting, testing, and evaluating results. This can include examining electrical characteristics such as current-voltage ratings or analyzing visual elements like solder joint integrity or component placement accuracy.

Quality control teams must also develop a process for verifying product specifications against customer expectations before delivery in order to guarantee satisfaction with their products. An effective quality management system should be implemented so that potential problems can be identified quickly and addressed appropriately in order to maintain high levels of customer service and trust. Ultimately, by establishing stringent protocols over every aspect of production you will ensure that your customers receive only top-notch products from your company.

Utilize Proper Testing Technology

When it comes to ensuring the highest quality in PCB assembly online technology, proper testing is essential. To ensure that all components are properly functioning and have been assembled correctly, a reliable testing system must be put into place. Quality control and testing should be conducted throughout the entire process of manufacturing a PCB – from design to delivery – with appropriate tests for each stage.

The most common tests include visual inspection, X-ray imaging, electrical test, environmental test, and functional test; however, there may also be some additional tests depending on the product specifications. All tests should adhere strictly to industry standards and use up-to-date equipment that can detect even the smallest flaws or mistakes. By adopting an effective testing strategy early on in production processes, companies can save time and money by avoiding costly rework or repairs later down the line.

Monitor Environmental Conditions

To ensure optimal performance and results from PCB assembly online technology, it is important to monitor environmental conditions. Quality control and testing processes should be regularly checked for temperature, pressure, humidity levels, air flow rate, and dust particles in order to keep equipment operating efficiently.

To ensure optimal performance and results from PCB assembly online technology, it is important to monitor environmental conditions. Quality control and testing processes should be regularly checked for temperature, pressure, humidity levels, air flow rate, and dust particles in order to keep equipment operating efficiently.

Any fluctuations or irregularities in these conditions must be identified quickly so that corrective action can be taken to maintain the integrity of the system. Additionally, it is also necessary to monitor any potential sources of interference or disruption such as electromagnetic fields. By monitoring environmental conditions closely and responding promptly when abnormalities are detected, production teams can help ensure quality control and testing standards are met effectively.

Implement Automated Inspection and Test Processes

Automated inspection and test processes are an important part of any PCB assembly online technology. By automating the process, manufacturers can reduce costs associated with manual inspections and tests while ensuring that quality standards are met or exceeded. Automated testing also helps to identify issues faster than traditional methods, allowing for a quicker response time should defects arise. The implementation of automated inspection and test processes typically starts by gathering information on existing products, such as specifications and drawings, which will be used to create the control parameters for automation. Once these parameters have been established, they can then be programmed into the system being used for automation.

Automated inspection and test processes are an important part of any PCB assembly online technology. By automating the process, manufacturers can reduce costs associated with manual inspections and tests while ensuring that quality standards are met or exceeded. Automated testing also helps to identify issues faster than traditional methods, allowing for a quicker response time should defects arise. The implementation of automated inspection and test processes typically starts by gathering information on existing products, such as specifications and drawings, which will be used to create the control parameters for automation. Once these parameters have been established, they can then be programmed into the system being used for automation.

This programming may include various algorithms which use data gathered from production lines in order to ensure accuracy during testing procedures; this data is then compared against quality standards set out by the manufacturer to detect any discrepancies between actual performance and expected results. Additionally, many systems allow operators to modify or adjust settings based on their own criteria without having to change code manually.

Once implemented, automated inspection and test processes offer numerous benefits over traditional approaches including improved consistency across all components tested; reduced labor costs due to fewer personnel being required; increased efficiency through shorter production cycles; better maintainability since fewer resources are needed for maintenance tasks; higher product reliability as potential errors are eliminated earlier in the manufacturing cycle; cost savings thanks to lower amounts of scrap produced per product unit; and improved management capabilities since more detailed reports about each operation can be created quickly.